How should a micrometer be stored when not in use?

Fully closed

Slightly openWith a small gap between the spindle and anvil

In a vertical position

With a small gap between the spindle and anvil

A micrometer, also known as a micron, is a unit of length in the metric system. It is equal to one millionth of a meter (0.000001 meter or 10⁻⁶ meters). The micrometer is commonly used in science and engineering for measurements where precision at the scale of cells, bacteria, and materials engineering is required. The symbol for the micrometer is “µm”.

It is commonly used in mechanical engineering and machining to measure the thickness, diameters, or lengths of very small objects with fine resolution. A typical micrometer consists of a calibrated screw gauge that can measure the distance displaced by the screw in fractions of a millimeter or inches, typically to an accuracy of 0.01 mm or 0.0001 inches. Micrometers come in various types, including outside micrometers (for measuring external dimensions), inside micrometers (for measuring internal dimensions), and depth micrometers (for measuring depths).

Here are some common tools used to measure in the micrometer range:

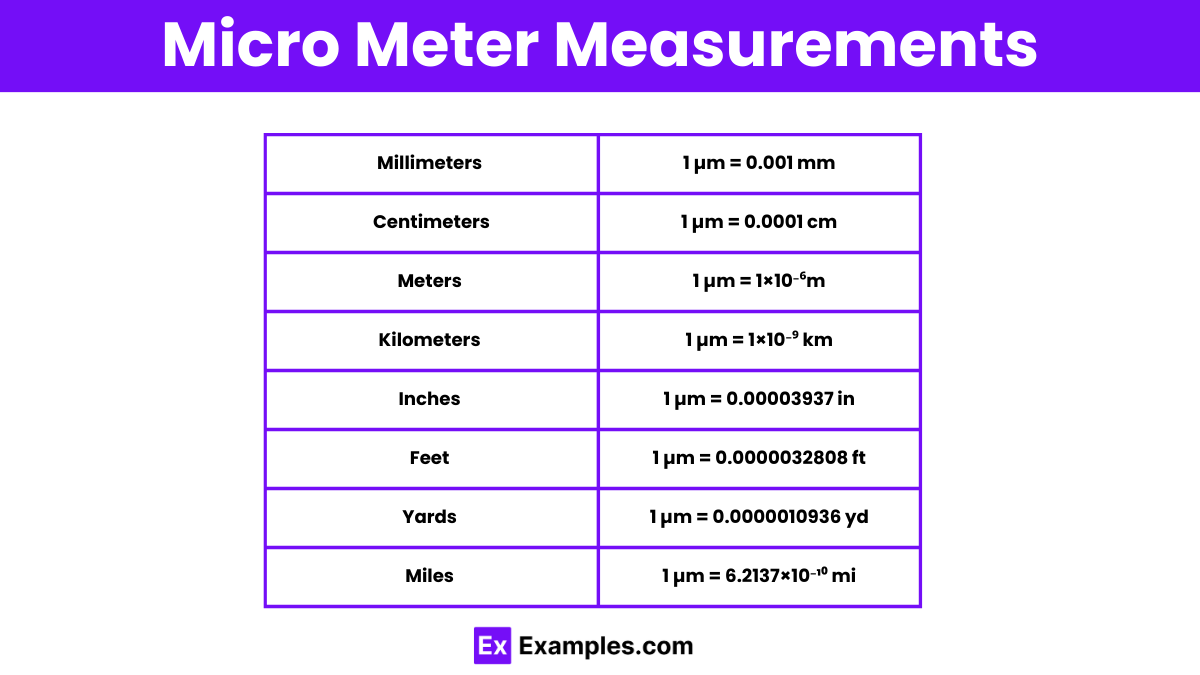

Here’s a table showing the conversion of micrometers to other common units of length:

| Length Unit | Conversion from Micrometers (µm) |

|---|---|

| Millimeters | 1 µm = 0.001 mm |

| Centimeters | 1 µm = 0.0001 cm |

| Meters | 1 µm = 1×10⁻⁶m |

| Kilometers | 1 µm = 1×10⁻⁹ km |

| Inches | 1 µm = 0.00003937 in |

| Feet | 1 µm = 0.0000032808 ft |

| Yards | 1 µm = 0.0000010936 yd |

| Miles | 1 µm = 6.2137×10⁻¹⁰ mi |

Understanding how to convert micrometers to other units of length is essential when working with microscopic measurements or in fields requiring precise dimensional accuracy. Whether you’re calculating the thickness of materials, sizing components, or analyzing microscopic structures, accurate conversion between micrometers and other units ensures precise measurements and compatibility across different scales. Here’s a straightforward guide to converting micrometers to and from other common units of length:

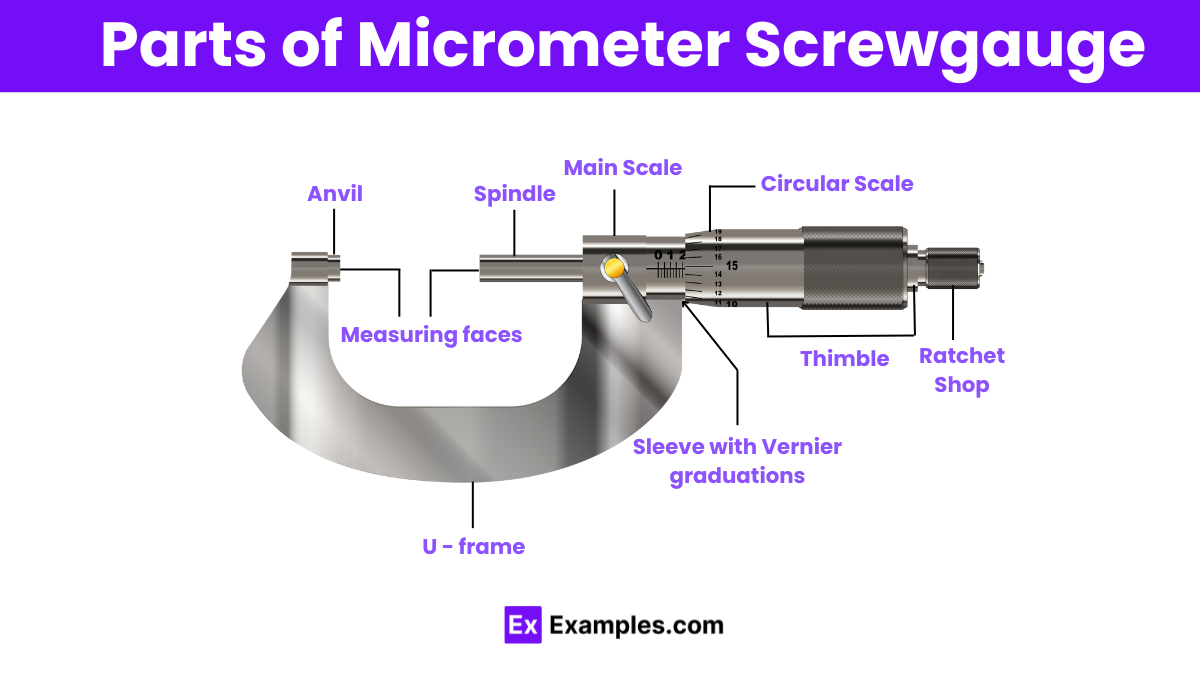

Here are the main parts of a typical outside micrometer, which is used to measure external dimensions such as the diameter of rods or the thickness of blocks:

The heart of the micrometer is the micrometer screw, a precision-threaded mechanism that controls the spindle’s movement. This screw allows for very fine adjustments, translating small turns into exact changes in distance, which is crucial for measuring with high precision and repeatability. The accuracy of the micrometer largely depends on the precision of these threads, making the micrometer screw the central, most critical component of the tool.

The operating principle of a micrometer is based on the mechanical advantage provided by a finely threaded screw. As the screw rotates, it moves the spindle linearly toward or away from the anvil at a precise rate. This movement allows the micrometer to measure small distances with high accuracy. The reading is taken from the alignment of the scale on the thimble with the fixed scale on the sleeve, representing the distance between the spindle and the anvil, which corresponds to the thickness or outer dimension of the object being measured.

The least count of a micrometer refers to the smallest measurement increment that the tool can accurately read. For most standard micrometers, the least count is typically 0.01 millimeters (0.0001 inches), achieved by the precision of its finely threaded screw. This allows the micrometer to provide highly accurate and repeatable measurements for fine applications.

Here’s a table comparing the key differences between a micrometer and a Vernier caliper:

| Feature | Micrometer Screw Gauge | Vernier Caliper |

|---|---|---|

| Precision | Typically higher, usually around 0.01 mm | Generally lower, usually around 0.02 mm |

| Measurement Range | Limited to a specific range per device | Wider range, can measure different sizes easily |

| Operation | More complex, requires careful handling | Simpler and quicker to use |

| Cost | Generally more expensive due to precision | Less expensive |

| Versatility | Primarily for thickness or external diameters | Can measure internal and external dimensions, depths, and steps |

| Readout | Usually a rotating spindle and fixed anvil | Sliding scale and movable jaw |

| Suitability | Best for very precise measurements in a limited capacity | Good for a variety of measurements with reasonable precision |

| Durability | High, with sturdy construction | Generally durable but can vary by build quality |

| Ease of Learning | Steeper learning curve for accurate use | Easier to learn and master |

Here are the basic steps to correctly use a micrometer:

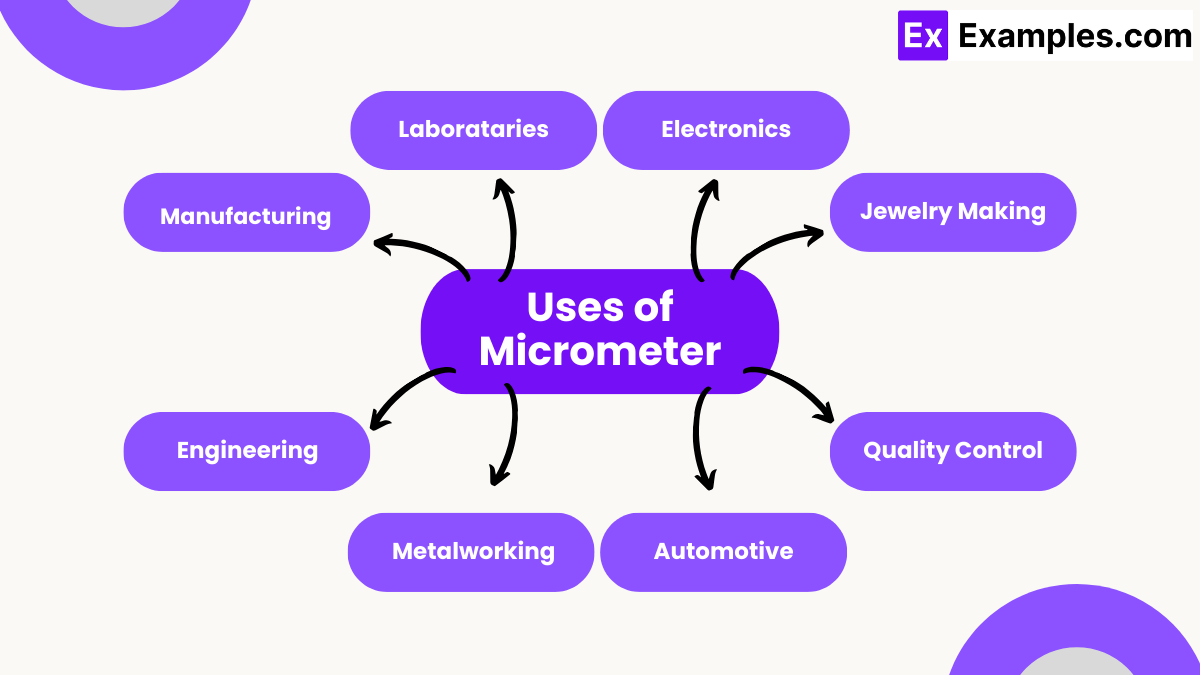

A micrometer is a highly precise measuring tool used in various fields for accurate measurement of small distances, thicknesses, or diameters. Here are some common uses of a micrometer:

One micrometer (µm) is equivalent to one millionth of a meter, or 0.001 millimeters. It’s a microscopic unit of measurement used for very small distances.

The formula to calculate the measurement using a micrometer is:

Measured Value = Main Scale Reading + (Circular Scale Reading × Circular Scale Least Count)

A micrometer is a unit of length in the metric system, equivalent to one millionth of a meter, which is 0.001 millimeters or 0.0001 centimeters.

The micrometer, as a precision measuring instrument, was developed by William Gascoigne in the early 17th century, originally for use in telescopic sights to improve astronomical observations.

Text prompt

Add Tone

10 Examples of Public speaking

20 Examples of Gas lighting

How should a micrometer be stored when not in use?

Fully closed

Slightly openWith a small gap between the spindle and anvil

In a vertical position

With a small gap between the spindle and anvil

What should be done if a micrometer gives inconsistent readings?

Replace it immediately

Recalibrate it

Use more force in measurement

Ignore the variations

What material is typically used for the frame of a high-quality micrometer?

Plastic

Steel

Aluminum

Titanium

Why is it important to clean the anvil and spindle of a micrometer regularly?

To maintain accuracy

To keep it looking new

To prevent rust

To increase its range

What is a micrometer used for?

Measuring temperature

Measuring weight

Measuring small distances with high precision

Measuring speed

Which part of the micrometer is rotated to take a measurement?

Frame

Anvil

Thimble

Spindle

How is the accuracy of a micrometer generally expressed?

In millimeters

In micrometers

In centimeters

In meters

Which part of the micrometer holds the object being measured?

Frame

Anvil

Thimble

Sleeve

What type of micrometer is used to measure the internal diameter of a hole?

Outside micrometer

Inside micrometer

Depth micrometer

Thread micrometer

How do you ensure the micrometer is zeroed correctly before taking a measurement?

Rotate the thimble to the maximum position

Close the spindle gently to the anvil and check the zero reading

Measure a known reference standard

Both b and c

Before you leave, take our quick quiz to enhance your learning!